Health Sciences Machine Shop

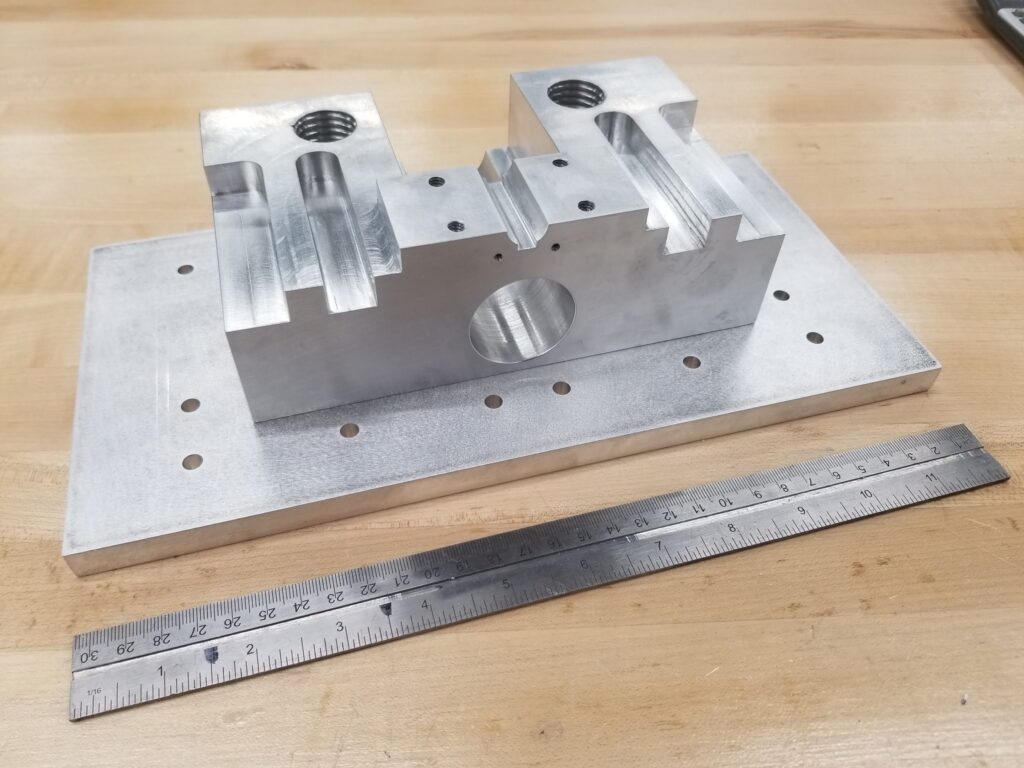

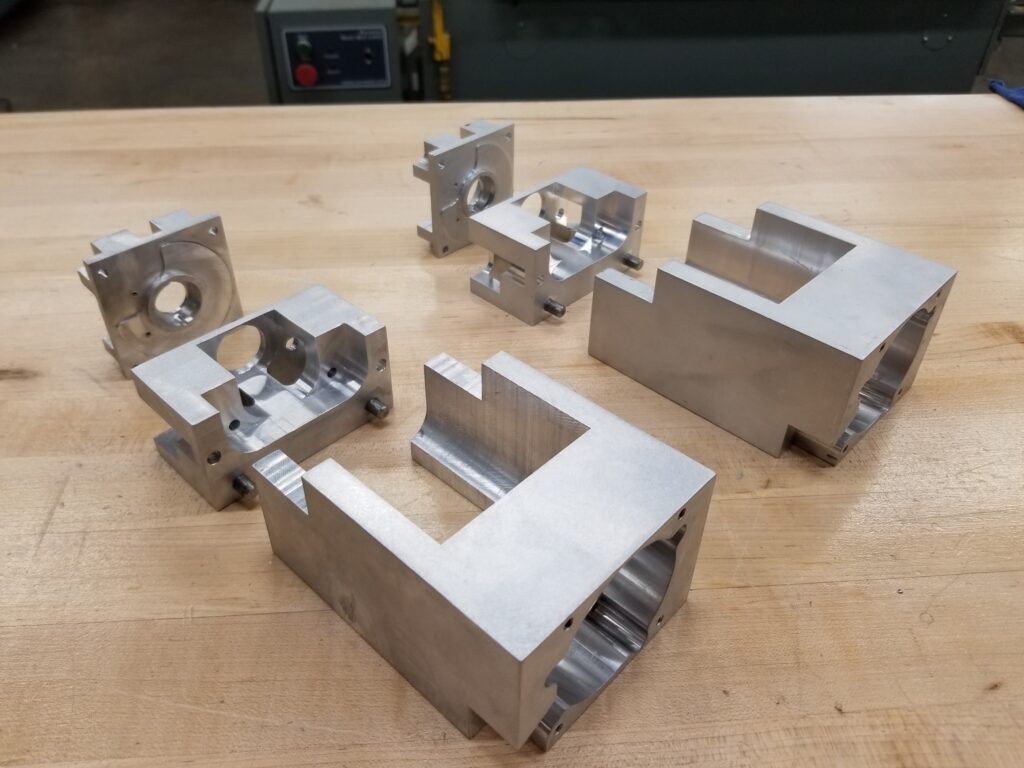

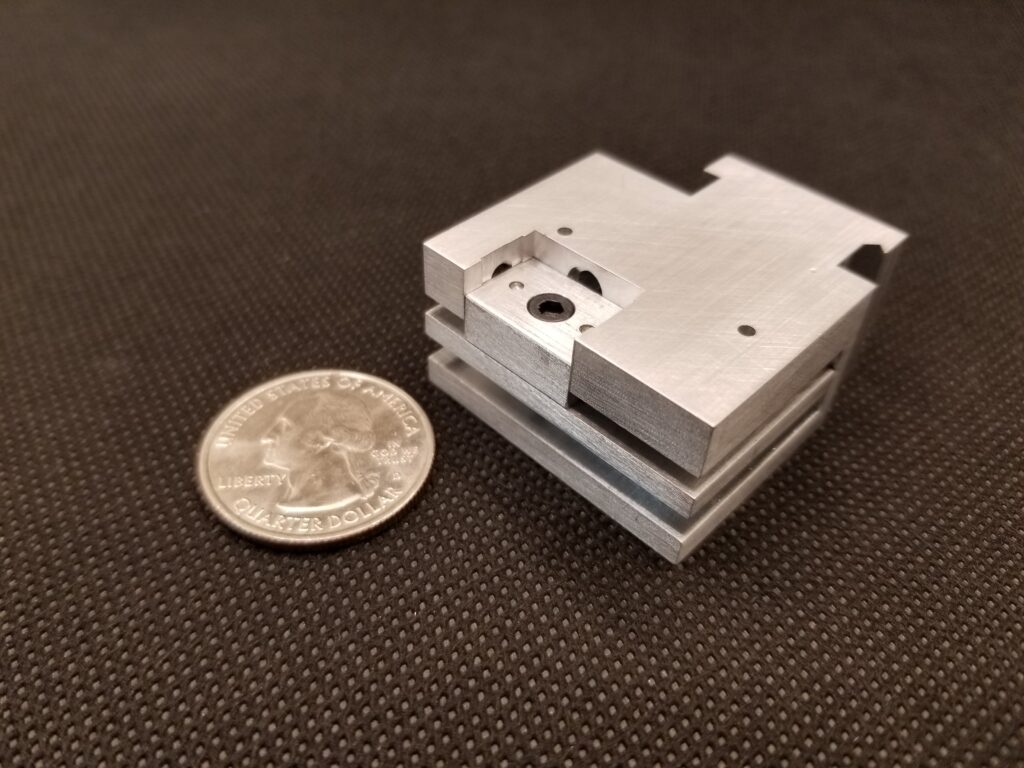

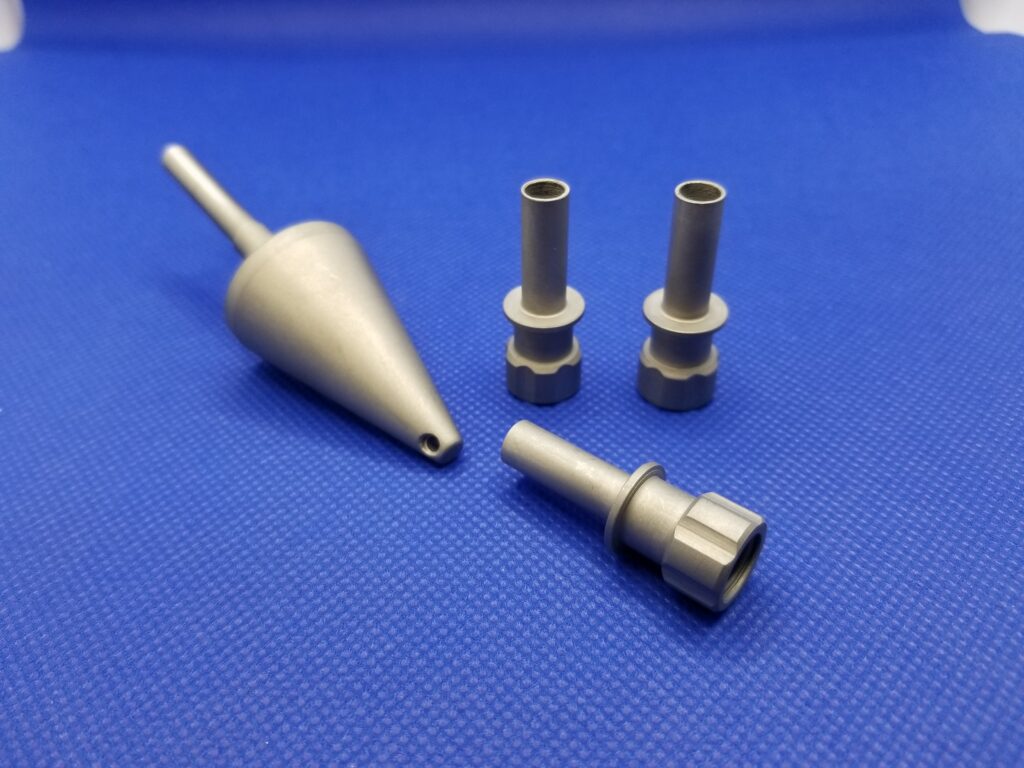

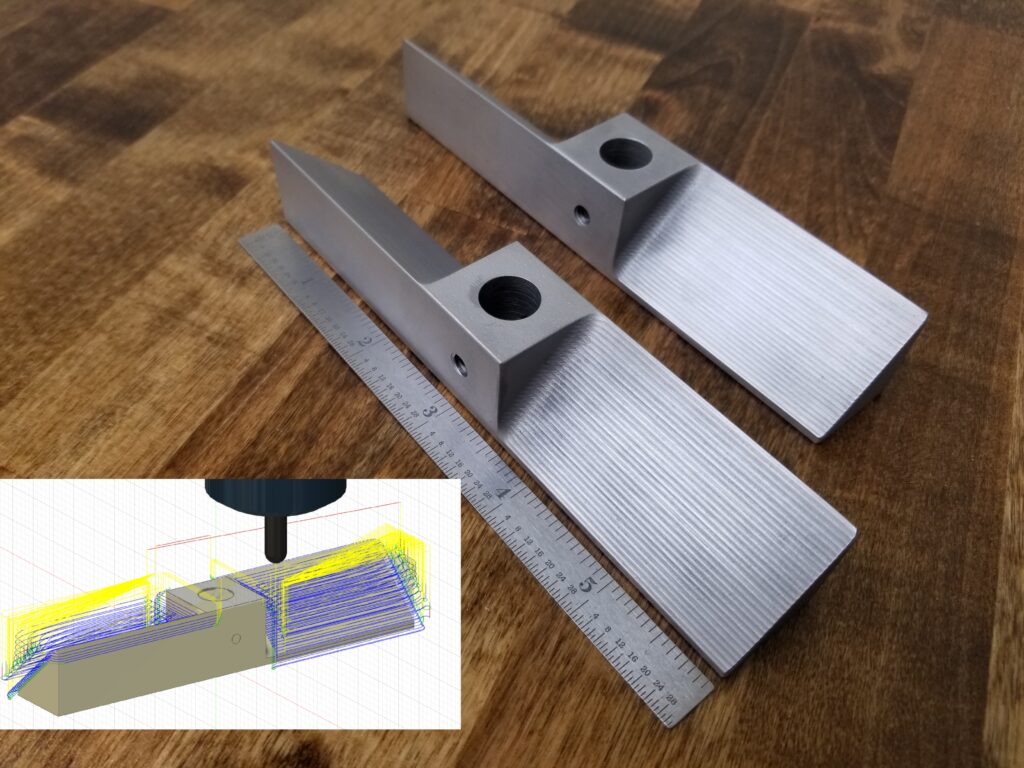

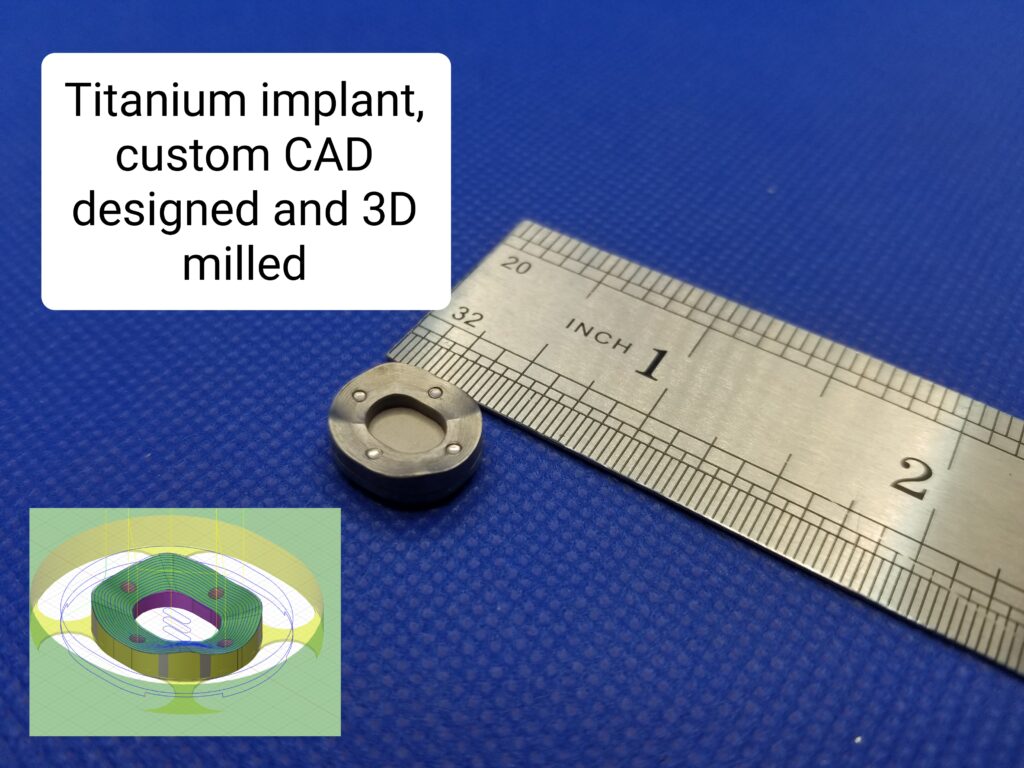

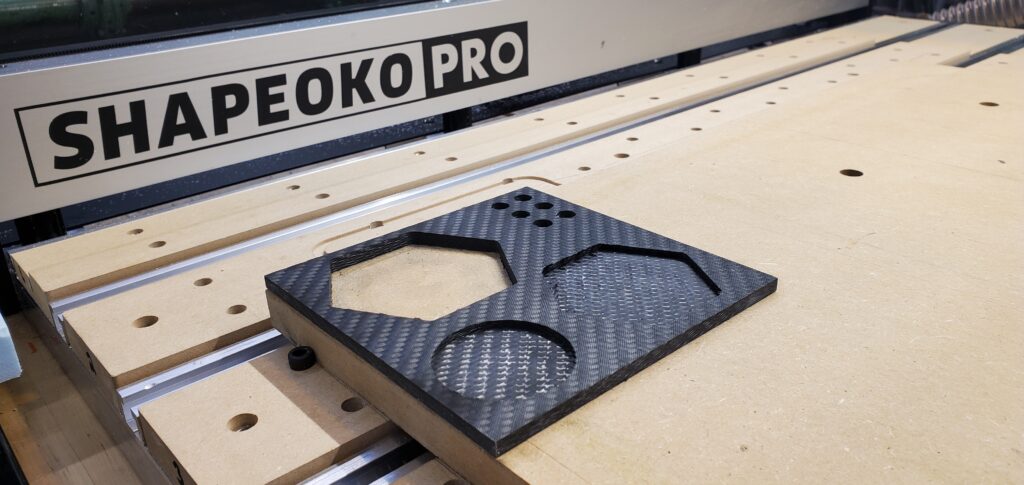

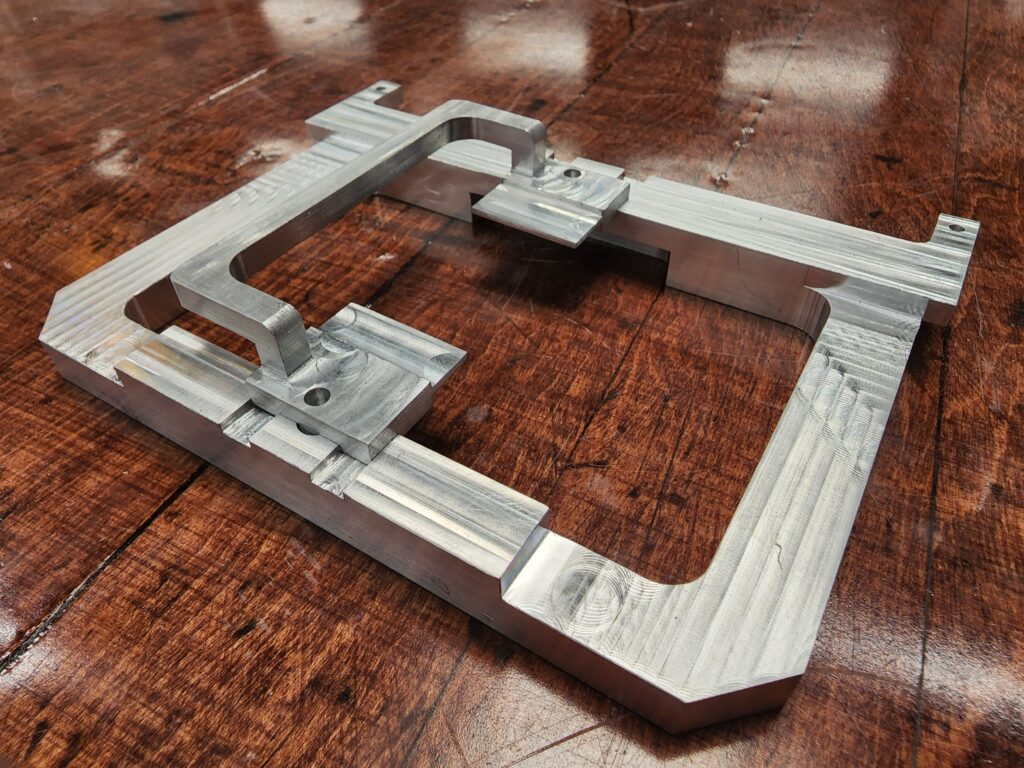

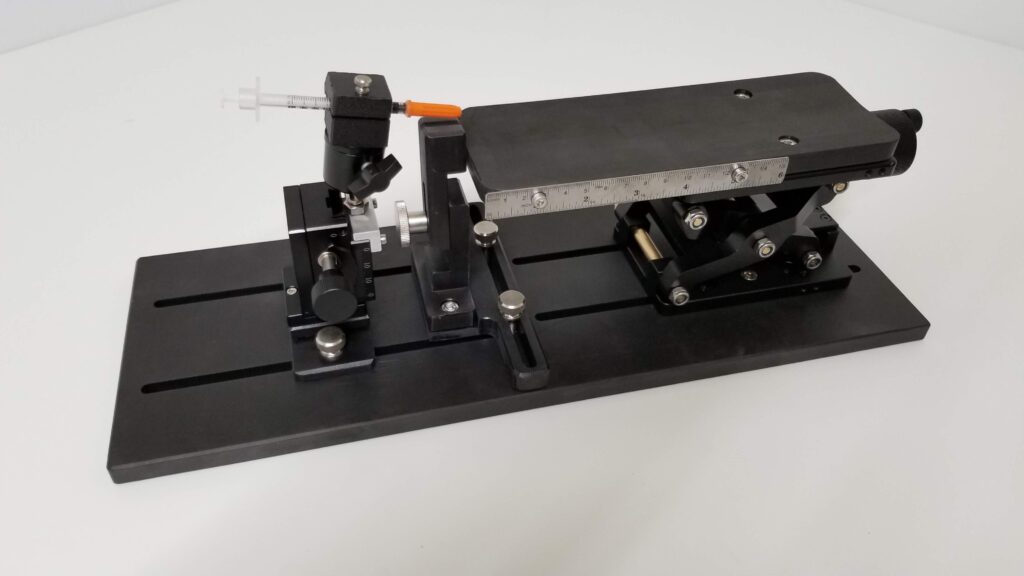

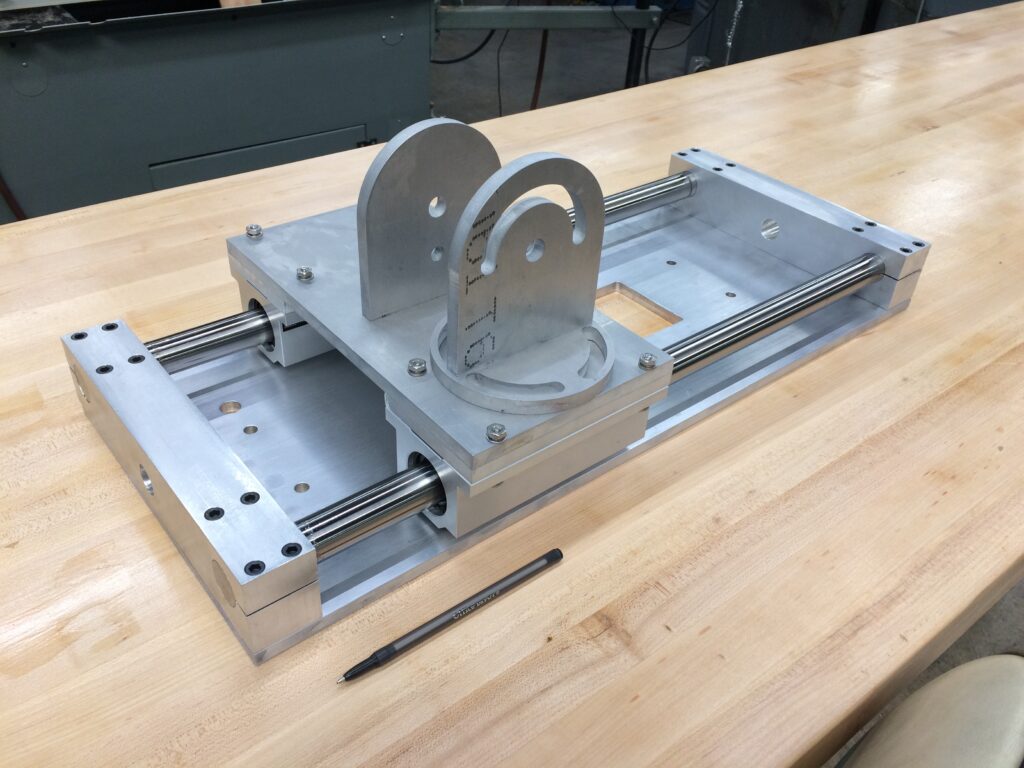

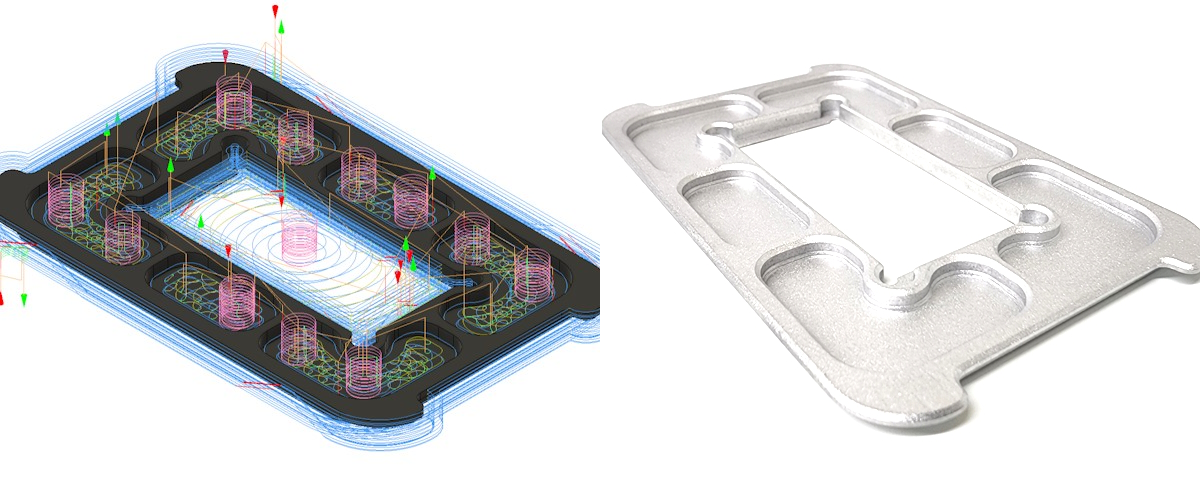

Students, professors, and researchers face a complex environment requiring a comprehensive approach to projects. Having expertise in multiple manufacturing techniques and integrating them all into one hybrid project means we can help you achieve the best value on your project. We can also broaden your budget by repairing or modifying existing equipment to your exact needs. Our facility has the fastest turnaround and enables you to come in with just a concept and finish with a device custom designed and built that can achieve your goals. From concept, to design, to prototype, to final product all in this facility. Browse our gallery of projects to visualize our capabilities and contact us for a consultation.

Available Services

Development Modification Repair

Surgical equipment

Research equipment

Microscope accessories and peripherals

Animal habitats and research equipment

Shop Services

CAD services

Reverse engineering

Manufacturing and engineering consultation

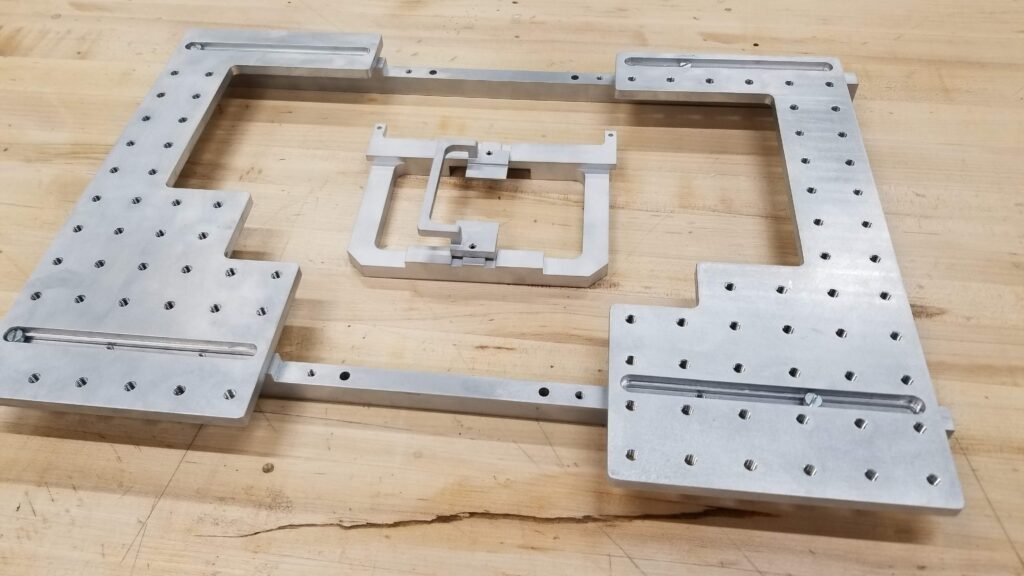

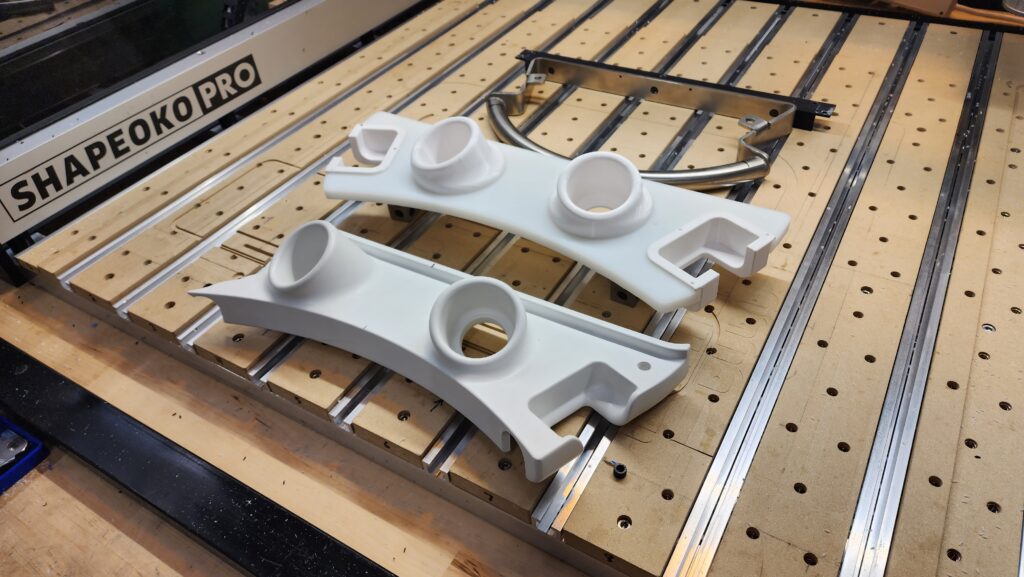

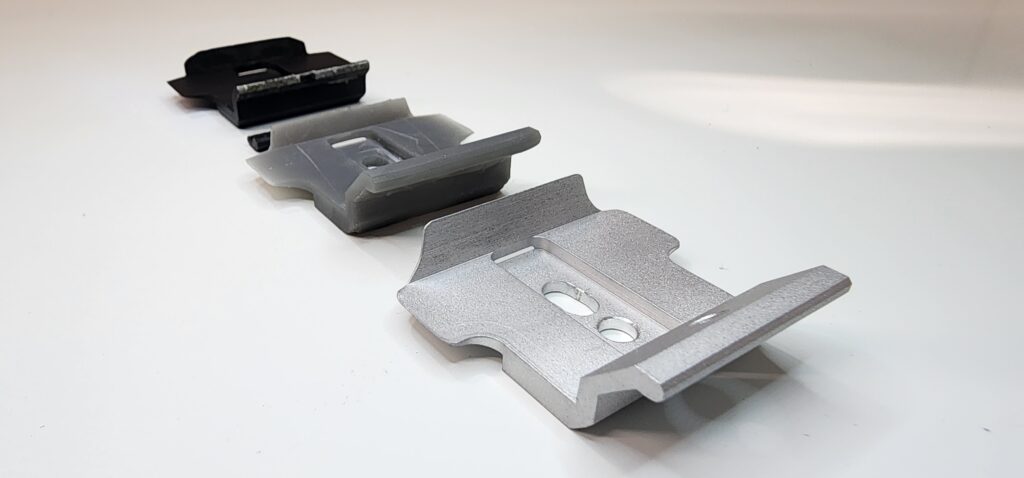

CNC milling and lathe work

3D printing with FMD and resin machines and multiple materials

General equipment repair

Plastic laser cutting, engraving, and fabrication

Metal fabrication and welding

Hybrid manufacturing techniques

Requesting Services

Existing users may login directly to the Resource Scheduling System to schedule or order services. This system is cores-wide and uses University of Utah uNID authentication.

After the work authorization has been approved please contact us with the username and account title so we can to look up the account. If you, your managers, or principal investigator already have an account please provide their username and the description/title on the account. Once the work authorization has been approved please contact us to begin work on your project. Our typical turnaround time is 1 to 2 weeks for most projects.

Hours of Operation

7:30 am to 4:00 pm

Monday - Friday

Shop Phone Number

801-581-3218

Address

Machine Shop

729 Arapeen Drive

Neuroscience Imaging

Building 888, Room 1520

Salt Lake City, UT

Parking / Access

Park in the south patient parking lot.

Go down the long hallway.

Locate the double doors marked "Machine Shop".

Our office is located down on the right side of

the hall as you walk east.

Citing Our Facility

Acknowledgments

We would like to thank you for acknowledging the our facility. This recognition allows us to highlight the impact of your work and demonstrates the important contributions of our facility makes to research across the University of Utah. The recognition our core receives from your acknowledgments also aids in receiving grants and further funding for equipment and services we can provide to our users.

Self-Run Services / Instrumentation Usage:

In published papers that used instruments at our facility and notably involved staff members please use the following format:

We acknowledge (facility name) at the University of Utah for use of equipment (insert instrument/service details here), and thank (insert any notable staff member – if desired) for their assistance.

Assisted Services:

In published papers where a staff member assisted you in addition to the requested services please use the following format:

We acknowledge (facility name) at the University of Utah for use of equipment (insert instrument/service details here), and thank (insert staff member-required) for their assistance in (service provided).

Collaboration:

For publications resulting from collaborations that assisted with the methodologies, planning process and execution of your experiment in addition to equipment usage we require Co-author attribution on your publication for our facility and any staff members who provided substantial contributions to the originating project.